What is LSPI?

In an effort to provide the highest performing lubricants that are safe and effective in any engine, Royal Purple High Performance API licensed engine oils are formulated with only the most advanced additive technology that is tested and proven to be effective at reducing and eliminating lubricant induced Low-Speed Pre-Ignition (LSPI). Royal Purple API SN/ILSAC GF-7 licensed engine oils meet or exceed all industry and OEM requirements in reducing LSPI events while also continuing to provide the highest level of lubrication performance and wear protection for the engine.

In the continuing effort to increase passenger car and light truck fuel economy, automakers have employed a “down-sizing” and “downspeeding” strategy to current vehicle powertrains. The down-sizing is accomplished with the use of Turbocharged Gasoline Direct Injection (TGDI) engines.

The TGDI engines provide the torque and power output of larger displacement, non-turbo engines while returning fuel economy approaching that of smaller displacement, non-turbo engines.

For example, late model TGDI 2.0 Liter engines commonly produce power levels equaling 3.0L to 3.5L V-6 engines from 5 to 10 years ago. The extensive fuel, ignition and boost adjustability and control that TGDI engines have allows them to be tuned with maximum torque achieved at very low engine speeds (by 2,000 rpm is typical). By optimizing torque to lower operating speeds, greater fuel economy is possible. The down-speeding of the powertrain involves the use of transmissions with an increased number of gear ratios with smaller steps between each ratio.

Automatic transmissions with 8 to 10 forward gear ratios are now common, while 4 to 6 speed automatic transmissions were most common in the recent past. With the increase in gear ratios and the small step change between each gear, the power train can keep the engine speed low and near the torque peak of the engine while allowing good acceleration and highway speeds.

Continuously Variable Transmissions (CVTs) are used in the same manner as they provide a step-less, continuous change in gear ratio with infinite gear ratios theoretically available. By using a smaller displacement engine that is kept in a low speed and efficient operating range, fuel economy is optimized.

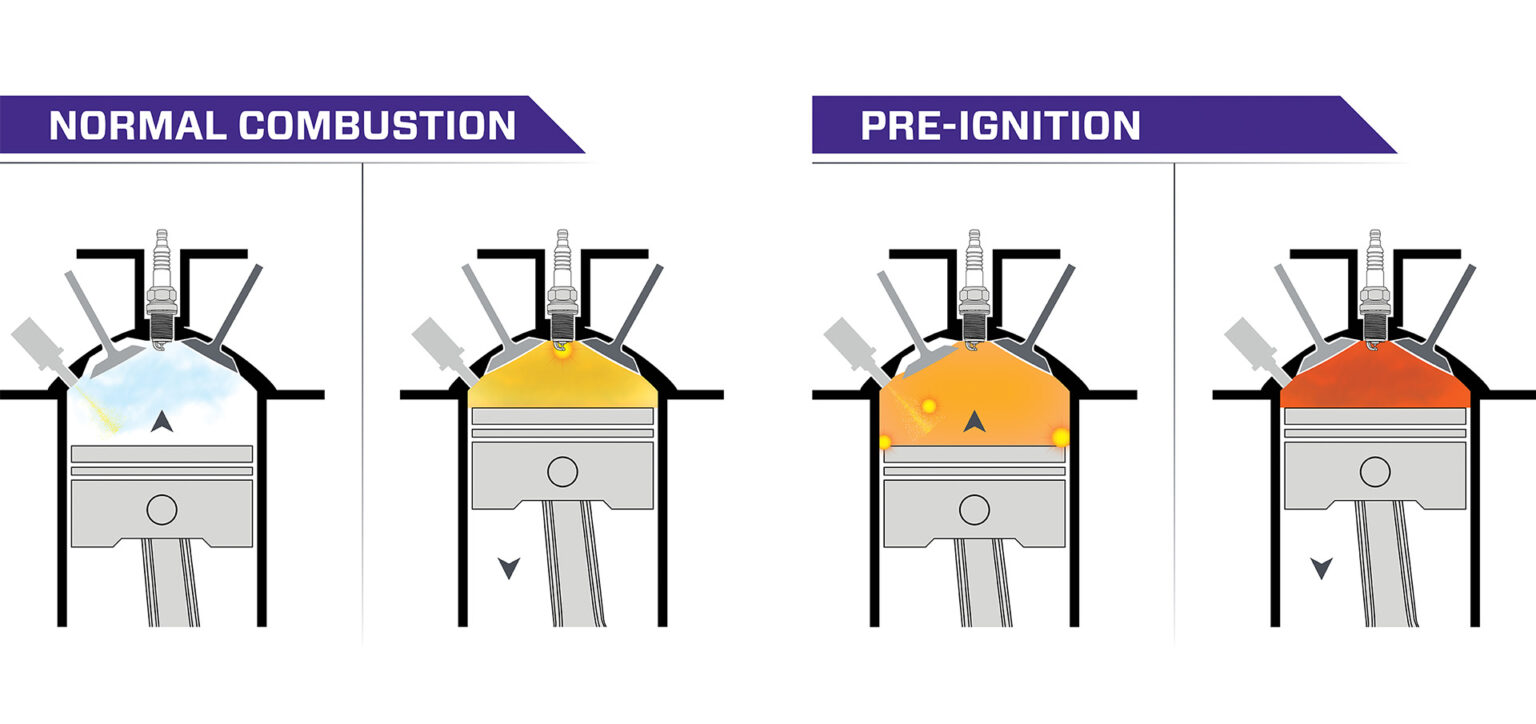

Pre-ignition and detonation, commonly referred to as “knock”, are abnormal combustion events that can occur in gasoline engine combustion chambers. Preignition and detonation result in a huge spike in combustion pressure and temperature that often results in damage to the engine. TGDI engines offer very high power density (power per displacement) and operate most efficiently at low engine speeds. Because of this, they are susceptible to a form of pre-ignition called Low-Speed Pre-Ignition (LSPI). Typical preignition and knock are caused by hot-spots on surfaces in the combustion chamber, and can be controlled by altering the spark ignition timing of the engine. LSPI tends to be caused by particles in the combustion chamber, either tiny liquid droplets of engine oil, or loose deposit particles caused by engine oil or fuel. Currently, the only way to control LSPI and help prevent it from occurring during engine operation is to increase the fuel delivered to the combustion chamber, which reduces the fuel economy of the engine.

Current research indicates that LSPI can be reduced with new chemistry technology used in gasolines and engine lubricants. Some chemical compounds traditionally used in fuel and lubricant additives may contribute directly to LSPI or to the formation of deposits that can cause LSPI.

In the continuing effort to increase passenger car and light truck fuel economy, automakers have employed a “down-sizing” and “downspeeding” strategy to current vehicle powertrains. The down-sizing is accomplished with the use of Turbocharged Gasoline Direct Injection (TGDI) engines.

The TGDI engines provide the torque and power output of larger displacement, non-turbo engines while returning fuel economy approaching that of smaller displacement, non-turbo engines.

For example, late model TGDI 2.0 Liter engines commonly produce power levels equaling 3.0L to 3.5L V-6 engines from 5 to 10 years ago. The extensive fuel, ignition and boost adjustability and control that TGDI engines have allows them to be tuned with maximum torque achieved at very low engine speeds (by 2,000 rpm is typical). By optimizing torque to lower operating speeds, greater fuel economy is possible. The down-speeding of the powertrain involves the use of transmissions with an increased number of gear ratios with smaller steps between each ratio.

Automatic transmissions with 8 to 10 forward gear ratios are now common, while 4 to 6 speed automatic transmissions were most common in the recent past. With the increase in gear ratios and the small step change between each gear, the power train can keep the engine speed low and near the torque peak of the engine while allowing good acceleration and highway speeds.

Continuously Variable Transmissions (CVTs) are used in the same manner as they provide a step-less, continuous change in gear ratio with infinite gear ratios theoretically available. By using a smaller displacement engine that is kept in a low speed and efficient operating range, fuel economy is optimized.

Pre-ignition and detonation, commonly referred to as “knock”, are abnormal combustion events that can occur in gasoline engine combustion chambers. Preignition and detonation result in a huge spike in combustion pressure and temperature that often results in damage to the engine. TGDI engines offer very high power density (power per displacement) and operate most efficiently at low engine speeds. Because of this, they are susceptible to a form of pre-ignition called Low-Speed Pre-Ignition (LSPI). Typical preignition and knock are caused by hot-spots on surfaces in the combustion chamber, and can be controlled by altering the spark ignition timing of the engine. LSPI tends to be caused by particles in the combustion chamber, either tiny liquid droplets of engine oil, or loose deposit particles caused by engine oil or fuel. Currently, the only way to control LSPI and help prevent it from occurring during engine operation is to increase the fuel delivered to the combustion chamber, which reduces the fuel economy of the engine.

Current research indicates that LSPI can be reduced with new chemistry technology used in gasolines and engine lubricants. Some chemical compounds traditionally used in fuel and lubricant additives may contribute directly to LSPI or to the formation of deposits that can cause LSPI.