The Royal Purple Advantage

ROYAL PURPLE ADDITIVE TECHNOLOGY ALLOWS PLANTS TO ACHIEVE SIGNIFICANT SAVINGS THROUGH SUPERIOR LUBRICATION

Synerlec® additive technology is the most versatile additive technology and the cornerstone of the product line. Royal Purple lubricants for turbines, pumps, compressors, blowers, hydraulics, gears, refrigeration systems, motor oils and more contain Synerlec additive technology. It forms a tough, ionic, slippery, chemical film on all metal surfaces. The result is an oil film that is thicker and tougher than other lubricants and micro-mends contacting metal surfaces.

In addition to their superior ability to fully separate and lubricate metal surfaces, Royal Purple lubricants offer the additional advantages listed below.

Longer Oil Life

Royal Purple oils formulated with Synerlec additive technology last considerably longer than other mineral and synthetic oils. Synerlec additive technology protects against oil oxidation. Oxidation causes oils to break down; to thicken; and to form corrosive acids, sludge, varnish or lacquer deposits in equipment. Synerlec additive technology greatly increases oil life, reducing the amount of oil purchased and in need of disposal. Equipment will remain cleaner, and it will have a longer life.

Excellent Corrosion Protection

Synerlec additive technology provides superior protection against rust and corrosion in both saltwater and freshwater environments. Royal Purple Synerlec additive technology ionically bonds with all metal surfaces to displace moisture. Synerlec’s tough film strength protects during operation, acts as a preservative oil during shutdown, and provides instant lubrication upon startup until a full fluid oil film is established.

Rapidly Separates From Water

Water in oil means death to bearings. Many oils form milky oil-water emulsions, which greatly shortens the life of both the oil and the equipment it lubricates. Royal Purple synthetic lubricants rapidly and completely separate from water, allowing water to easily be drained from the bottom of the oil reservoir.

Further Additive Technology

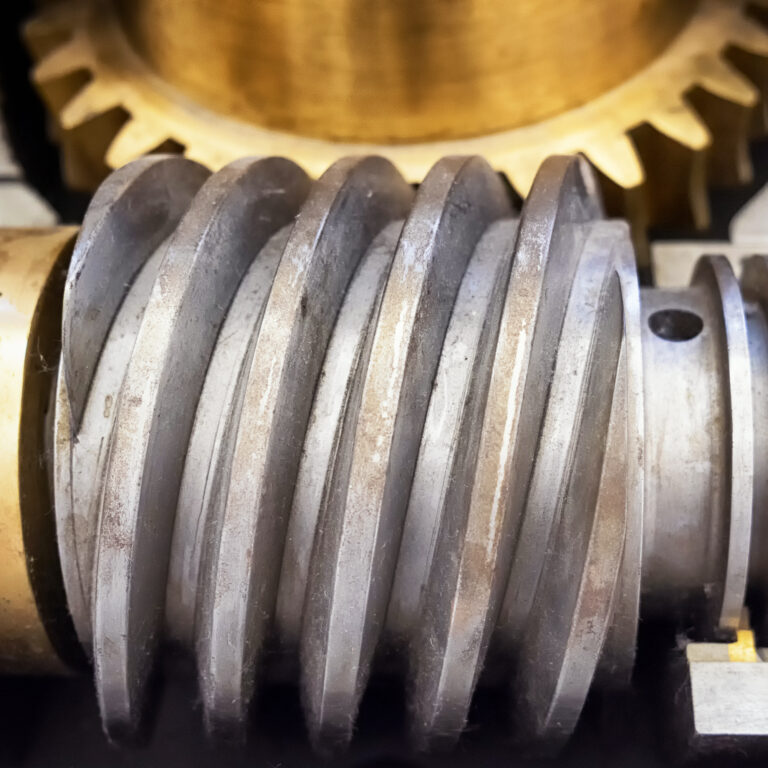

This exclusive additive technology offers all of the performance advantages of Synerlec additive technology plus superior protection against boundary lubrication (lubrication between two rubbing surfaces without development of a full-fluid lubricating film) conditions typically caused by heavy loads, shock loads and slow operating speeds. Royal Purple noncorrosive, extreme-pressure (EP) gear oils and greases contain Synslide™ additive technology.

Further Additive Technology

Royal Purple NSF Certified oils for H1 service for use in pharmaceutical and food service plants contain Purolec™ additive technology. This proprietary, stable, anti-wear additive technology reduces wear while still meeting the U.S. Food and Drug Administration’s CFR Title 21 Section 178.3620(b) purity regulation.

Further Additive Technology

DynaGlyde™ is a noncorrosive additive technology which contains special anti-wear additives, oiliness properties and cushioning molecules to provide the lubricity necessary to excel in worm gear lubrication.

Oil Cleanliness

Royal Purple lubricants are packaged in new, clean steel drums and pails to ensure fluid cleanliness. Additionally, Royal Purple bestselling bearing and hydraulic lubricants are filtered to a typical ISO 4406:99 cleanliness level of 14/13/11. (See pages 48-49 in technical appendix.) This is typically substantially cleaner than conventional lubricants delivered in steel drums or by bulk delivery. Bearing and hydraulic equipment manufacturers state that this improvement in oil cleanliness will increase bearing and hydraulic component life from 300 to 500 percent. (See pages 52-53 in technical appendix.) Royal Purple is the only lubricant manufacturer that has established these high cleanliness requirements for its standard products.

Saves Energy

Energy costs constitute the single largest expense of operating rotating equipment. The typical energy costs for rotating equipment are 20 to 25 times greater than direct maintenance costs. Royal Purple’s premium, synthetic lubricants with Synerlec and Synslide additive technologies have extremely low coefficients of friction. They are proven to save energy over other mineral and synthetic oils in rotating equipment. In fact, Royal Purple lubricants frequently produce energy savings from 1 to 3 percent or more. In most instances, these savings exceed the total cost of the oil within several months. It turns what was once an oil expense into a profit. Total elimination of lubrication expenses would not produce significant cost savings from the total operating costs of the rotating equipment. However, significant savings can be achieved through small percentage reductions in the large expense items: energy and maintenance costs.